Global CPG manufacturers lose over $50 billion annually to quality failures and recalls – a staggering figure that underscores why excellence in manufacturing isn’t just about meeting standards, it’s about survival. In an industry where a single contaminated batch can destroy decades of brand equity, achieving quality and consistency at scale becomes the ultimate competitive advantage.

The Foundation of CPG Manufacturing Excellence

Manufacturing excellence in the consumer packaged goods industry goes far beyond basic quality control. It’s a holistic approach that weaves together people, processes, and technology to create products that consistently meet consumer expectations while maximizing operational efficiency.

Here’s what separates truly excellent CPG manufacturers from the rest: they don’t just react to quality issues – they prevent them. This proactive mindset requires building quality into every step of the manufacturing process, from raw material sourcing to final packaging.

Quality Management Systems That Actually Work

The backbone of any successful CPG operation is a robust quality management system (QMS). But here’s the thing – not all QMS implementations deliver the same results. The most effective systems share several key characteristics:

- Real-time monitoring capabilities: Instead of discovering problems after production runs, leading manufacturers use sensors and automated systems to catch deviations as they happen

- Integrated data collection: Every touchpoint in the manufacturing process feeds data into a central system, creating a complete picture of product quality

- Predictive analytics: Advanced systems don’t just report what happened – they predict what’s likely to happen based on historical patterns and current conditions

- Automated corrective actions: When deviations occur, the system automatically adjusts parameters to bring the process back into specification

The Human Element in Manufacturing Excellence

Technology is crucial, but people remain at the heart of manufacturing excellence. The most successful CPG companies invest heavily in their workforce, creating a culture where quality is everyone’s responsibility, not just the QC department’s.

This culture starts with proper training. Workers need to understand not just what to do, but why they’re doing it. When someone understands how their role impacts the final product, they’re more likely to take ownership of quality outcomes.

Scaling Quality: The Biggest Challenge in CPG Manufacturing

Most businesses miss this critical point: what works at small scale often breaks down when you try to scale up. A process that produces perfect results for 1,000 units per day might fail catastrophically at 100,000 units per day.

The challenge isn’t just about volume – it’s about maintaining consistency across multiple production lines, shifts, facilities, and even countries. Each variable introduces potential points of failure that can compromise quality.

Process Standardization Across Multiple Facilities

When CPG companies operate multiple manufacturing facilities, consistency becomes exponentially more complex. The same product produced in different locations must meet identical specifications, regardless of local conditions, equipment variations, or cultural differences.

Here’s what works for standardization at scale:

- Detailed standard operating procedures (SOPs): Document every critical step with enough detail that any trained operator can achieve the same results

- Regular cross-facility audits: Compare processes and outcomes across locations to identify and eliminate variations

- Centralized quality metrics: Use the same measurement systems and criteria across all facilities

- Knowledge sharing platforms: When one facility solves a problem, share that solution immediately with all other locations

Supply Chain Quality Management

Your product quality is only as good as your weakest supplier. This reality makes supplier quality management a critical component of manufacturing excellence. Leading CPG companies don’t just audit their suppliers annually – they integrate supplier quality data into their real-time monitoring systems.

The most effective approach involves creating supplier scorecards that track multiple metrics: quality performance, delivery reliability, responsiveness to issues, and continuous improvement efforts. Suppliers who consistently underperform get additional support or replacement.

Technology-Driven Quality Assurance

The reality is that modern CPG manufacturing requires sophisticated technology to achieve excellence at scale. Manual quality checks, while still important, can’t keep pace with high-volume production demands.

Statistical Process Control (SPC) and Real-Time Analytics

Statistical Process Control has evolved far beyond simple control charts. Modern SPC systems use advanced algorithms to detect subtle patterns that might indicate quality issues before they become problems.

These systems continuously analyze production data, looking for trends, correlations, and anomalies that human operators might miss. When the system detects a potential issue, it can automatically alert operators, adjust process parameters, or even stop production if necessary.

Internet of Things (IoT) in Manufacturing

IoT sensors throughout the manufacturing process provide unprecedented visibility into production conditions. Temperature sensors, vibration monitors, pressure gauges, and chemical analyzers continuously feed data into central monitoring systems.

This might surprise you: the most valuable IoT applications often monitor seemingly mundane factors. A vibration sensor on a mixer might detect bearing wear before it affects product consistency. A humidity sensor in the packaging area might prevent adhesion problems that could lead to package failures.

Artificial Intelligence and Machine Learning

AI and machine learning take quality management to the next level by identifying patterns that humans and traditional statistical methods can’t detect. These systems learn from historical data to predict quality outcomes based on current process conditions.

For example, an AI system might discover that products manufactured on Tuesday afternoons have slightly higher defect rates – not because of any obvious process change, but due to subtle factors like operator fatigue, ambient temperature, or raw material age.

Regulatory Compliance and Quality Standards

CPG manufacturers must navigate an increasingly complex regulatory environment while maintaining operational efficiency. Different products face different regulatory requirements, and global companies must comply with regulations in multiple jurisdictions simultaneously.

FDA and International Standards

Food and beverage manufacturers must comply with FDA regulations, including the Food Safety Modernization Act (FSMA), which emphasizes preventive controls rather than reactive responses. Similarly, other CPG products must meet various safety and quality standards depending on their category and target markets.

The key to managing regulatory compliance is building it into your quality systems from the ground up, rather than treating it as an add-on. When compliance is integrated into standard processes, it becomes automatic rather than burdensome.

Third-Party Certifications and Audits

Many retailers and consumers now expect third-party certifications like SQF, BRC, or ISO standards. These certifications provide external validation of your quality systems and can open doors to new markets and customers.

But here’s what many companies get wrong: they pursue certifications without first ensuring their underlying systems are robust. The certification should validate excellence that already exists, not create it.

Continuous Improvement Culture

Manufacturing excellence isn’t a destination – it’s an ongoing journey. The best CPG companies create cultures where continuous improvement is embedded in daily operations, not just special projects.

Employee Engagement in Quality Initiatives

Frontline employees often have the best insights into process improvements because they work with the equipment and procedures every day. Creating formal channels for employee suggestions and ensuring those suggestions get evaluated and responded to can generate significant improvements.

Recognition programs that celebrate quality improvements, not just production volumes, help reinforce the importance of excellence over speed.

Data-Driven Decision Making

Every improvement initiative should be based on data, not opinions or assumptions. This requires collecting and analyzing the right metrics consistently over time. The most useful metrics often combine quality, efficiency, and cost data to provide a complete picture of manufacturing performance.

Cost Management Without Compromising Quality

One of the biggest challenges in CPG manufacturing is controlling costs while maintaining quality standards. It’s tempting to cut corners when facing pressure to reduce expenses, but quality compromises often cost more in the long run through recalls, customer complaints, and brand damage.

Total Cost of Quality Analysis

Smart manufacturers look at the total cost of quality, which includes prevention costs, appraisal costs, internal failure costs, and external failure costs. Often, spending more on prevention and appraisal reduces the much higher costs of internal and external failures.

For example, investing in better raw material testing might increase upfront costs but prevent expensive production runs of defective products.

Lean Manufacturing Principles

Lean manufacturing principles can reduce costs while improving quality by eliminating waste and streamlining processes. The key is implementing lean methodically, with proper training and change management, rather than simply cutting resources.

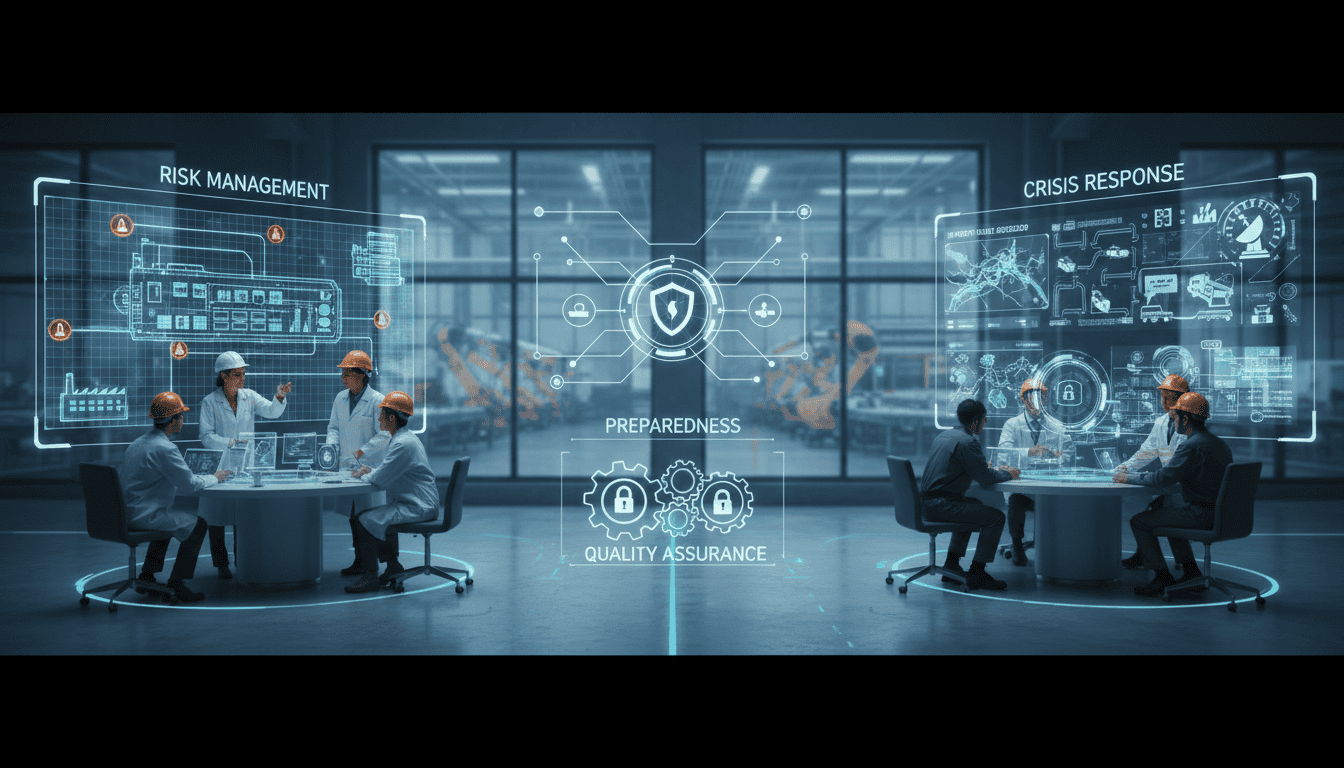

Risk Management and Crisis Response

Even the best quality systems can’t prevent every possible problem. Excellent CPG manufacturers prepare for potential issues with robust risk management and crisis response plans.

Traceability Systems

Complete traceability – knowing exactly which raw materials went into which products and where those products went – is essential for managing quality issues when they occur. Modern traceability systems can track individual units or batches throughout the entire supply chain.

Recall Preparedness

Having a detailed recall plan isn’t just about regulatory compliance – it’s about protecting your brand and customers when problems occur. The best recall plans include pre-written communications, clear role assignments, and regular drills to ensure everyone knows what to do.

Future Trends in CPG Manufacturing Excellence

The landscape of CPG manufacturing continues evolving rapidly. Several trends are shaping the future of quality and consistency at scale:

- Digital twins: Virtual replicas of manufacturing processes that allow for simulation and optimization without disrupting actual production

- Blockchain for supply chain transparency: Immutable records of product journey from raw materials to consumer

- Advanced robotics: More sophisticated automation that can handle complex tasks while maintaining consistency

- Sustainability integration: Quality systems that also optimize for environmental impact and resource efficiency

Measuring Success: Key Performance Indicators

You can’t manage what you don’t measure. The most effective CPG manufacturers track a balanced set of KPIs that reflect all aspects of manufacturing excellence:

Quality Metrics

- First-pass yield rates

- Customer complaint rates

- Defect rates by product line

- Supplier quality scores

- Regulatory compliance rates

Operational Metrics

- Overall equipment effectiveness (OEE)

- Production schedule adherence

- Changeover times

- Energy efficiency per unit

- Waste reduction percentages

The key is not just collecting these metrics, but using them to drive continuous improvement decisions and hold teams accountable for results.

Conclusion

Manufacturing excellence in the CPG industry requires a complete commitment to quality at every level of the organization. It’s not enough to have good intentions or even good processes – you need integrated systems, engaged people, and the right technology working together toward common goals.

The companies that master this balance don’t just avoid the $50 billion in losses we mentioned at the start – they build competitive advantages that translate directly to market share, customer loyalty, and profitable growth.

Success in today’s competitive marketplace requires more than just excellent manufacturing. You need marketing strategies that effectively communicate your quality story to consumers. At Beast Creative Agency, we help CPG manufacturers translate their operational excellence into compelling brand narratives that drive sales and build lasting customer relationships. Our data-driven approach ensures your quality investments generate maximum return through strategic marketing campaigns that resonate with your target audience.