A single contaminated batch can destroy decades of brand trust and cost millions in recalls, litigation, and lost revenue. For consumer packaged goods (CPG) companies, quality control isn’t just about meeting standards—it’s about protecting consumers and preserving the brand reputation that drives long-term profitability.

The Foundation of CPG Quality Control

Quality control in the CPG industry goes far beyond basic product testing. It’s a complete system that starts with raw material sourcing and continues through manufacturing, packaging, distribution, and even post-market surveillance. This approach protects both consumers and brands from the devastating consequences of quality failures.

The reality is that today’s consumers expect perfect products every time. They don’t just want products that work—they demand products that are safe, consistent, and meet the exact standards promised on the packaging. When companies fail to deliver, social media amplifies complaints instantly, and regulatory bodies respond with swift action.

Core Components of Effective Quality Systems

Modern CPG quality control systems rely on several interconnected elements:

- Supplier qualification programs that verify raw material quality before production begins

- In-process monitoring that catches deviations during manufacturing

- Finished product testing that confirms specifications are met

- Environmental monitoring that ensures clean production conditions

- Traceability systems that track products from ingredients to consumer

Regulatory Landscape and Compliance Requirements

CPG companies operate in one of the most regulated environments in business. The complexity increases exponentially when products cross international borders, as each market brings its own set of requirements and enforcement mechanisms.

Key Regulatory Bodies and Standards

Here’s what works when navigating the regulatory maze:

FDA Regulations: In the United States, the Food and Drug Administration sets strict guidelines for food, beverages, cosmetics, and over-the-counter medications. The Food Safety Modernization Act (FSMA) requires companies to identify potential hazards and create prevention plans, not just respond to problems after they occur.

International Standards: Companies selling globally must comply with standards like ISO 22000 for food safety management, BRC (Brand Reputation Compliance) for consumer products, and various regional requirements in the European Union, Asia-Pacific, and Latin America.

Industry-Specific Certifications: Different product categories require specialized certifications. Organic products need USDA Organic certification, while cosmetics may require cruelty-free verification or specific safety assessments.

The Cost of Non-Compliance

Most businesses underestimate the true cost of regulatory violations. Beyond immediate fines, companies face:

- Production shutdowns and facility closures

- Product recalls that can cost millions per incident

- Legal liability from consumer harm

- Permanent damage to brand reputation

- Loss of retail partnerships and distribution channels

Risk Management in CPG Quality Control

Effective risk management starts with understanding that quality issues can emerge at any point in the product lifecycle. Smart companies don’t wait for problems to appear—they actively hunt for potential failure points and build systems to prevent them.

Hazard Analysis and Critical Control Points (HACCP)

HACCP provides a systematic approach to identifying and controlling risks. Here’s how leading CPG companies use this framework:

- Conduct hazard analysis: Identify biological, chemical, and physical hazards that could affect product safety

- Determine critical control points: Find the stages where hazards can be prevented or eliminated

- Establish critical limits: Set measurable criteria that must be met at each control point

- Set up monitoring procedures: Create systems to track performance at critical control points

- Plan corrective actions: Define specific steps to take when monitoring shows a deviation

- Verify the system works: Regularly review and test the entire HACCP plan

- Keep detailed records: Document everything to prove compliance and enable continuous improvement

Supply Chain Risk Assessment

Modern CPG companies often source materials from dozens or hundreds of suppliers across multiple countries. This complexity creates numerous risk points that require careful management.

The key is developing a risk-based approach to supplier oversight. High-risk suppliers—those providing critical ingredients or operating in regions with weak regulatory oversight—require more frequent audits and testing. Lower-risk suppliers can be managed through periodic reviews and performance monitoring.

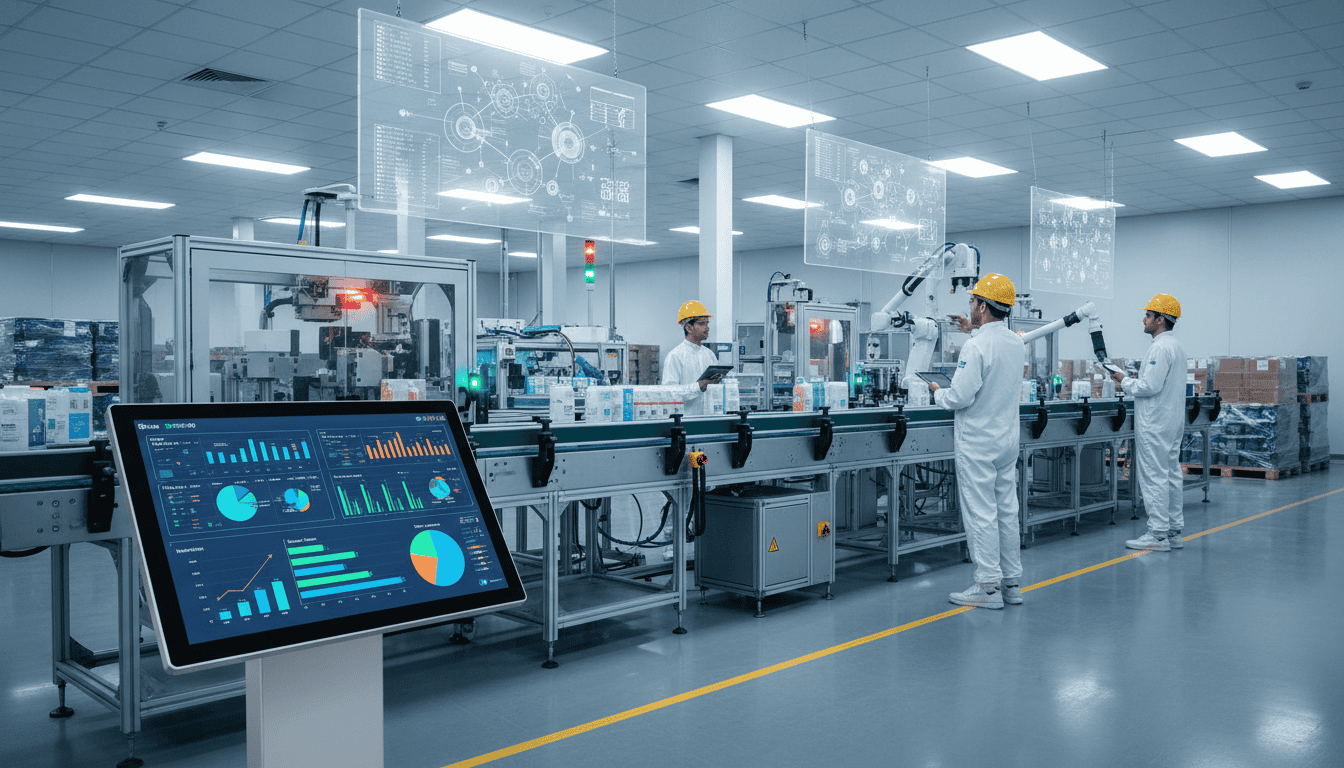

Technology and Innovation in Quality Assurance

Technology is transforming how CPG companies approach quality control. The days of relying solely on end-of-line testing and manual inspections are quickly ending.

Real-Time Monitoring Systems

Advanced sensors and Internet of Things (IoT) devices now provide continuous monitoring of critical parameters like temperature, humidity, pH levels, and contamination indicators. This real-time data allows manufacturers to catch deviations immediately, often before they affect product quality.

This might surprise you: some companies are now using artificial intelligence to analyze sensor data and predict quality issues before they occur. These predictive systems can identify patterns that human operators might miss, preventing problems instead of just detecting them.

Blockchain for Traceability

Blockchain technology is solving one of the CPG industry’s biggest challenges: complete supply chain traceability. When quality issues arise, companies need to quickly identify affected products and trace them back to their source.

Traditional paper-based systems can take days or weeks to complete this process. Blockchain-based traceability systems can provide complete product histories in minutes, enabling faster response times and more targeted recalls when necessary.

Laboratory Automation and Testing

Automated testing equipment is making it possible to test more products, more frequently, with greater accuracy than ever before. Robotic systems can run hundreds of tests simultaneously, providing statistically significant data that improves decision-making.

Advanced analytical methods like mass spectrometry and genetic sequencing are also becoming more accessible, allowing companies to detect contaminants and adulterants that traditional methods might miss.

Building a Culture of Quality

Here’s the thing about quality control: technology and procedures only work when people use them correctly. Building a strong quality culture requires commitment from leadership and engagement from every employee.

Training and Education Programs

Effective quality training goes beyond basic compliance requirements. The best programs help employees understand why quality matters, not just what they need to do. When workers understand how their actions affect product safety and consumer trust, they’re more likely to follow procedures consistently.

Key elements of successful training programs include:

- Role-specific training that focuses on how each job affects quality

- Regular refresher sessions to reinforce key concepts

- Hands-on exercises that simulate real-world quality challenges

- Clear communication about the consequences of quality failures

- Recognition programs that reward quality-focused behavior

Continuous Improvement Processes

Quality control systems must evolve continuously. Markets change, new risks emerge, and regulatory requirements shift. Companies that treat quality systems as static documents rather than living processes quickly fall behind.

Leading CPG companies use formal continuous improvement methodologies like Six Sigma or Lean Manufacturing to systematically identify and eliminate sources of variation and waste. These approaches provide structured frameworks for analyzing problems and testing solutions.

Crisis Management and Incident Response

Even the best quality systems occasionally fail. When they do, the company’s response can mean the difference between a minor setback and a major crisis that threatens the business’s survival.

Rapid Response Protocols

Time is critical during quality emergencies. Companies need pre-established protocols that enable quick decision-making without sacrificing thoroughness. Effective incident response plans include:

- Clear escalation procedures that get the right people involved quickly

- Predefined communication templates for different types of incidents

- Established relationships with regulatory bodies to facilitate reporting and cooperation

- Media response strategies that protect brand reputation while ensuring transparency

- Recovery plans that restore normal operations as quickly as possible

Recall Management

Product recalls are every CPG company’s nightmare, but they’re sometimes necessary to protect consumers. The key is executing recalls efficiently and transparently to minimize damage to consumer trust and brand reputation.

Successful recall management requires robust traceability systems that can quickly identify affected products, strong relationships with retail partners who can remove products from shelves, and clear communication strategies that keep consumers informed without creating unnecessary panic.

Measuring Quality Performance

What gets measured gets managed. CPG companies need robust metrics to track quality performance and identify improvement opportunities.

Key Performance Indicators (KPIs)

The most effective quality metrics balance leading indicators that predict problems with lagging indicators that measure outcomes. Important KPIs include:

- First-pass yield: The percentage of products that meet specifications on the first attempt

- Customer complaint rates: The frequency and severity of quality-related complaints

- Supplier performance scores: Metrics tracking supplier quality, delivery, and compliance

- Audit findings: The number and severity of issues identified during internal and external audits

- Cost of quality: The total cost of prevention, detection, and correction activities

Data Analysis and Reporting

Raw data only becomes useful when it’s analyzed and acted upon. Modern quality management systems use statistical analysis to identify trends, predict problems, and measure the effectiveness of improvement initiatives.

The reality is that many companies collect enormous amounts of quality data but struggle to turn it into actionable insights. Effective data analysis requires both the right tools and the right expertise to interpret results correctly.

Future Trends in CPG Quality Control

The quality control landscape continues to evolve rapidly. Companies that anticipate and adapt to these changes will maintain competitive advantages, while those that lag behind may find themselves struggling to meet rising consumer and regulatory expectations.

Sustainability and Quality Integration

Consumers increasingly expect products to be both high-quality and environmentally responsible. This trend is driving CPG companies to integrate sustainability considerations into their quality systems, from raw material sourcing to packaging design.

Personalization and Mass Customization

The trend toward personalized products creates new quality challenges. When companies produce thousands of product variations instead of a few standard formulations, traditional quality control approaches may not scale effectively. New approaches that combine automation with flexible testing protocols are emerging to address these challenges.

Digital Quality Management

Cloud-based quality management systems are enabling new levels of visibility and control. These systems can integrate data from multiple facilities, provide real-time dashboards for executives, and enable remote monitoring and management of quality processes.

Conclusion

CPG quality control has evolved from a cost center focused on catching defects to a strategic capability that drives consumer trust, regulatory compliance, and business growth. Companies that excel at quality control don’t just avoid problems—they build sustainable competitive advantages that translate directly to bottom-line results.

The most successful CPG companies treat quality as everyone’s responsibility, not just the quality department’s job. They invest in systems, training, and technology that prevent problems rather than just detecting them. Most importantly, they understand that quality control is ultimately about protecting consumers and building the trust that drives long-term brand loyalty.

At Beast Creative Agency, we help CPG companies communicate their quality commitments effectively to build consumer confidence and differentiate their brands in competitive markets. Our AI-enhanced campaigns and data-driven approach ensure your quality story reaches the right audience with maximum impact. Ready to transform your quality messaging into a competitive advantage? Let’s discuss how our proven strategies can elevate your brand’s reputation and drive measurable growth.