Consumer packaged goods companies lose an estimated $1.1 trillion annually due to poor demand forecasting – that’s roughly equivalent to the entire GDP of Australia. The culprit? Most CPG brands still rely on outdated forecasting methods that can’t keep pace with today’s volatile market conditions. Smart sales forecasting isn’t just about predicting numbers; it’s about creating a competitive advantage that directly impacts your bottom line.

Understanding CPG Sales Forecasting Fundamentals

Sales forecasting for consumer packaged goods differs significantly from other industries. You’re dealing with products that have shorter shelf lives, seasonal fluctuations, and consumer preferences that can shift overnight. Unlike B2B services where you might have predictable client relationships, CPG forecasting requires analyzing thousands of individual purchasing decisions across multiple retail channels.

The reality is that traditional forecasting methods – those spreadsheet-heavy approaches that many companies still use – simply can’t handle the complexity of modern CPG sales. You need systems that can process historical sales data, seasonal trends, promotional impacts, and external market factors simultaneously.

Key Components of Effective CPG Forecasting

- Historical sales analysis: Your past performance data serves as the foundation, but it’s just the starting point

- Market trend integration: Consumer behavior patterns, economic indicators, and industry shifts

- Seasonal adjustments: Understanding how holidays, weather, and calendar events affect demand

- Promotional impact modeling: Measuring how discounts, advertising campaigns, and product placements influence sales

- Competitive intelligence: Monitoring competitor actions and market share changes

Advanced Demand Prediction Strategies

Here’s what separates successful CPG brands from those constantly struggling with stockouts or overstock situations: they use multiple forecasting methods and combine them strategically.

Statistical Forecasting Methods

Moving averages and exponential smoothing provide your baseline predictions, but they’re not enough on their own. These methods work well for stable products with consistent demand patterns, but most CPG products don’t fall into that category.

Time series analysis takes things further by identifying underlying patterns in your sales data. It can spot trends that aren’t immediately obvious and help you understand cyclical behavior in your product categories.

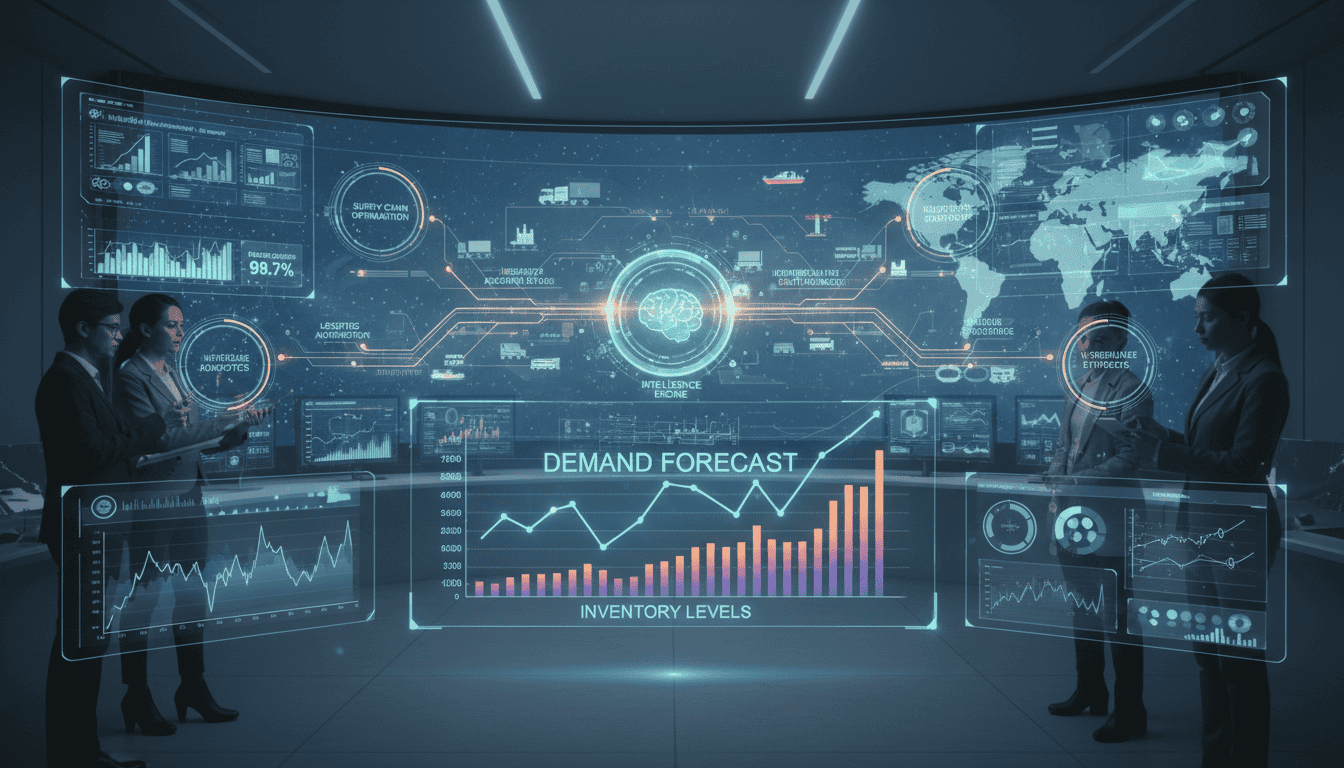

Machine Learning Applications

This might surprise you: machine learning isn’t just for tech companies anymore. CPG brands are using algorithms to process massive datasets and identify demand patterns that humans would miss.

Neural networks can analyze hundreds of variables simultaneously – everything from weather patterns to social media sentiment – and create forecasts that adapt in real-time as new data becomes available. The key is starting with clean, organized historical data and gradually adding complexity as your system learns.

External Data Integration

Smart CPG forecasting goes beyond your internal sales data. You need to incorporate:

- Economic indicators that affect consumer spending

- Weather data for products with seasonal sensitivity

- Social media trends and sentiment analysis

- Competitor pricing and promotional activities

- Supply chain disruption indicators

Inventory Management Integration

Forecasting accuracy means nothing if you can’t translate predictions into smart inventory decisions. The connection between demand forecasting and inventory management is where many CPG companies struggle.

Safety Stock Optimization

You can’t eliminate uncertainty, but you can manage it strategically. Safety stock calculations should factor in forecast accuracy, lead times, and the cost of stockouts versus carrying excess inventory.

Here’s the thing: different products in your portfolio require different safety stock strategies. High-margin items might justify higher safety stock levels, while products with short shelf lives need tighter inventory control.

Reorder Point Systems

Dynamic reorder points adjust based on forecasted demand changes, not just historical averages. This approach helps you avoid the common trap of ordering too late when demand spikes or ordering too much when demand softens.

The most effective reorder systems incorporate:

- Variable lead times based on supplier performance data

- Seasonal demand adjustments

- Promotional calendar integration

- Multi-location inventory balancing

Technology Solutions and Tools

Manual forecasting processes don’t scale with business growth. You need technology solutions that can handle increasing product complexity and market volatility.

Enterprise Resource Planning (ERP) Integration

Your forecasting system should connect seamlessly with your ERP platform. This integration ensures that demand forecasts automatically trigger procurement processes and inventory adjustments without manual intervention.

Most businesses miss this: ERP integration isn’t just about data sharing – it’s about creating automated workflows that reduce human error and speed up response times to demand changes.

Cloud-Based Forecasting Platforms

Cloud solutions offer scalability and real-time data processing that on-premise systems can’t match. They also provide access to external data sources and advanced analytics tools without requiring massive IT infrastructure investments.

Key features to look for include:

- Real-time data processing capabilities

- Multiple forecasting algorithm options

- Collaborative planning tools for cross-functional teams

- Mobile access for field sales teams

- API connectivity for third-party integrations

Measuring Forecast Accuracy

You can’t improve what you don’t measure. Forecast accuracy metrics help you understand which methods work best for different product categories and market conditions.

Key Performance Indicators

Mean Absolute Percentage Error (MAPE) gives you a straightforward accuracy measure, but it’s not the only metric that matters. Bias measurements help you understand if your forecasts consistently run high or low, while tracking forecast value added shows whether your sophisticated methods actually outperform simple baseline approaches.

Continuous Improvement Processes

The reality is that forecasting accuracy improves over time through systematic review and adjustment. Monthly forecast reviews should examine not just accuracy but also the business impact of forecast errors.

Document what caused significant forecast misses and adjust your methods accordingly. Were there promotional impacts you didn’t account for? Did competitor actions affect demand in ways your models didn’t predict? This information becomes valuable input for future forecasting cycles.

Common Forecasting Challenges and Solutions

Every CPG business faces similar forecasting obstacles. Here’s how to address the most common issues:

New Product Forecasting

Products without sales history require different approaches. Analogous product analysis looks at similar items in your portfolio and adjusts for known differences. Market research data, test market results, and comparable industry launches provide additional data points.

Promotional Impact Modeling

Promotions create demand spikes that can throw off your baseline forecasting models. Build separate models for promotional periods and account for both the immediate sales lift and any post-promotion demand reduction.

Managing Forecast Collaboration

Sales teams, marketing departments, and supply chain managers often have different perspectives on demand drivers. Create structured processes for incorporating input from different stakeholders without losing statistical rigor in your forecasting methods.

Future Trends in CPG Forecasting

The forecasting landscape continues evolving rapidly. Artificial intelligence and machine learning capabilities are becoming more accessible to mid-sized CPG companies, not just industry giants.

Real-time demand sensing uses point-of-sale data and other immediate indicators to adjust forecasts much faster than traditional monthly or weekly cycles. This capability becomes especially valuable for products with short life cycles or high demand volatility.

Predictive analytics integration with marketing campaigns allows you to forecast the demand impact of advertising spend and promotional activities before launching them, creating better coordination between marketing investments and inventory planning.

Building Your Forecasting Strategy

Start with your current forecasting accuracy baseline and identify the biggest pain points. Are you consistently running out of your best-selling items? Do you have too much slow-moving inventory taking up warehouse space? These issues point toward specific forecasting improvements that will deliver immediate business value.

Begin with one product category or market segment rather than trying to overhaul your entire forecasting process at once. Success with a focused pilot program builds internal confidence and provides lessons learned for broader implementation.

Remember that forecasting accuracy improvements of even a few percentage points can translate into significant cost savings and revenue improvements when applied across your entire product portfolio.

CPG sales forecasting requires balancing statistical rigor with business judgment, and the companies that master this balance gain sustainable competitive advantages in their markets. Your forecasting strategy should evolve continuously as you gather more data and refine your understanding of demand drivers.

At Beast Creative Agency, we understand how marketing campaigns and promotional activities impact demand patterns. Our AI-enhanced campaigns and data-driven approaches help CPG brands create more predictable demand signals, making your forecasting efforts more accurate and actionable. When your marketing generates consistent, measurable results, your entire supply chain benefits from improved predictability.